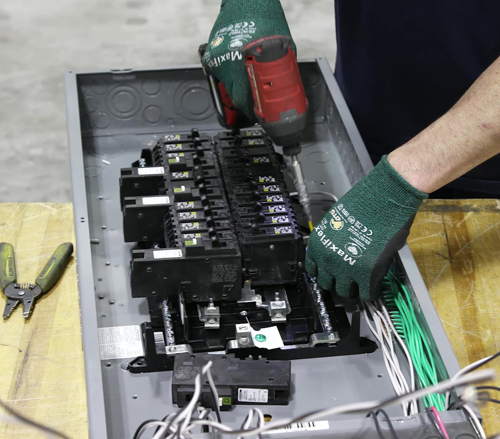

Pre-fabrication

Lighthouse Electric uses lean manufacturing techniques to continually evolve the efficiency of our construction process. By using standardized design and breaking all work down into specialized tasks we are able to shift a significant portion of the work scope from an on-site construction process to an off-site manufacturing process. This shift facilitates:

- Increased Quality Control

- Increased Safety Control

- Increased Schedule Control

- Increased Efficiency of Labor

The design team uses the quantity takeoff provided by the estimating department to identify key “must win” assemblies. These assemblies are then detailed using AutoCad MEP Fabrication. The detailing process allows us to break the work down into the following two functions:

- Fabrication – the joining together of individual components to form assemblies and the joining together of individual assemblies into modules.

- Installation – receive, place and connect assemblies and modules to the structure

Installation must be completed at the jobsite; fabrication can be completed anywhere. Fabricating assemblies and modules away from the jobsite increases our control of the work. Lighthouse Electric uses a combination of manufacturer partnerships and in house labor to meet our fabrication needs. To ensure fabricated assemblies fit right the first time, all fabrication is modeled in AutoCAD MEP Fabrication by the design team.